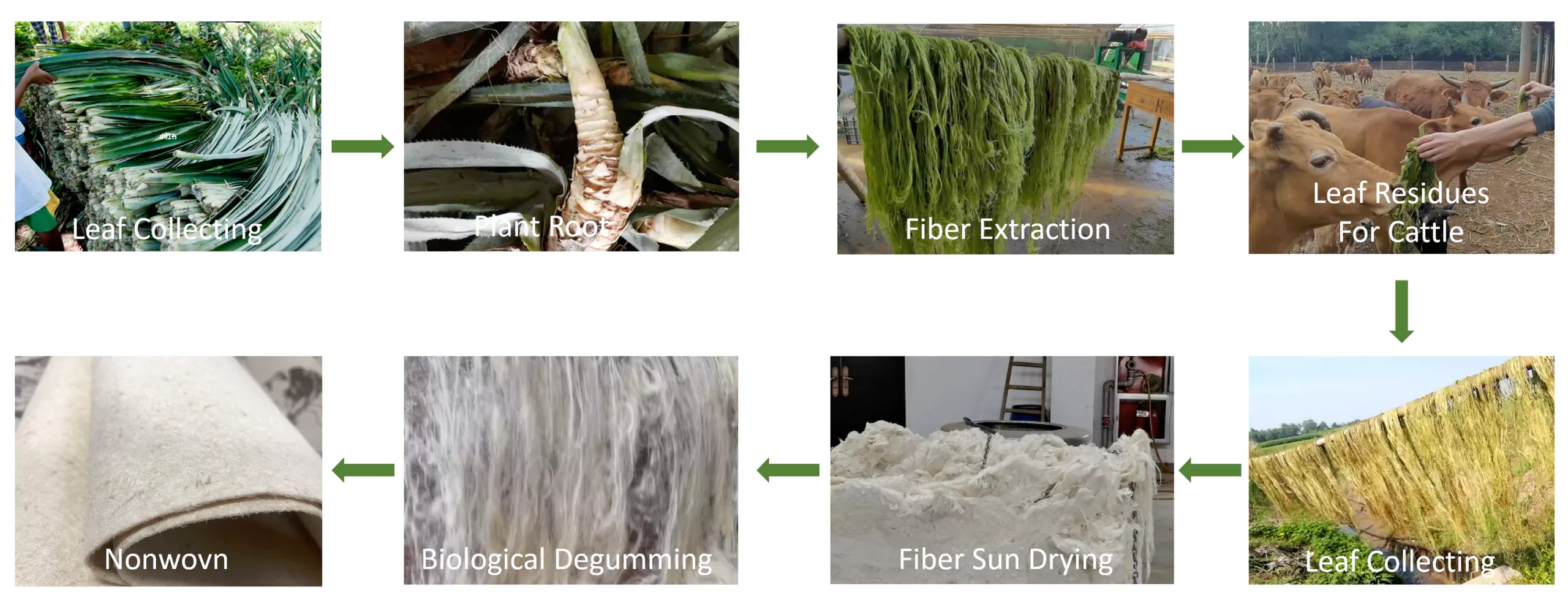

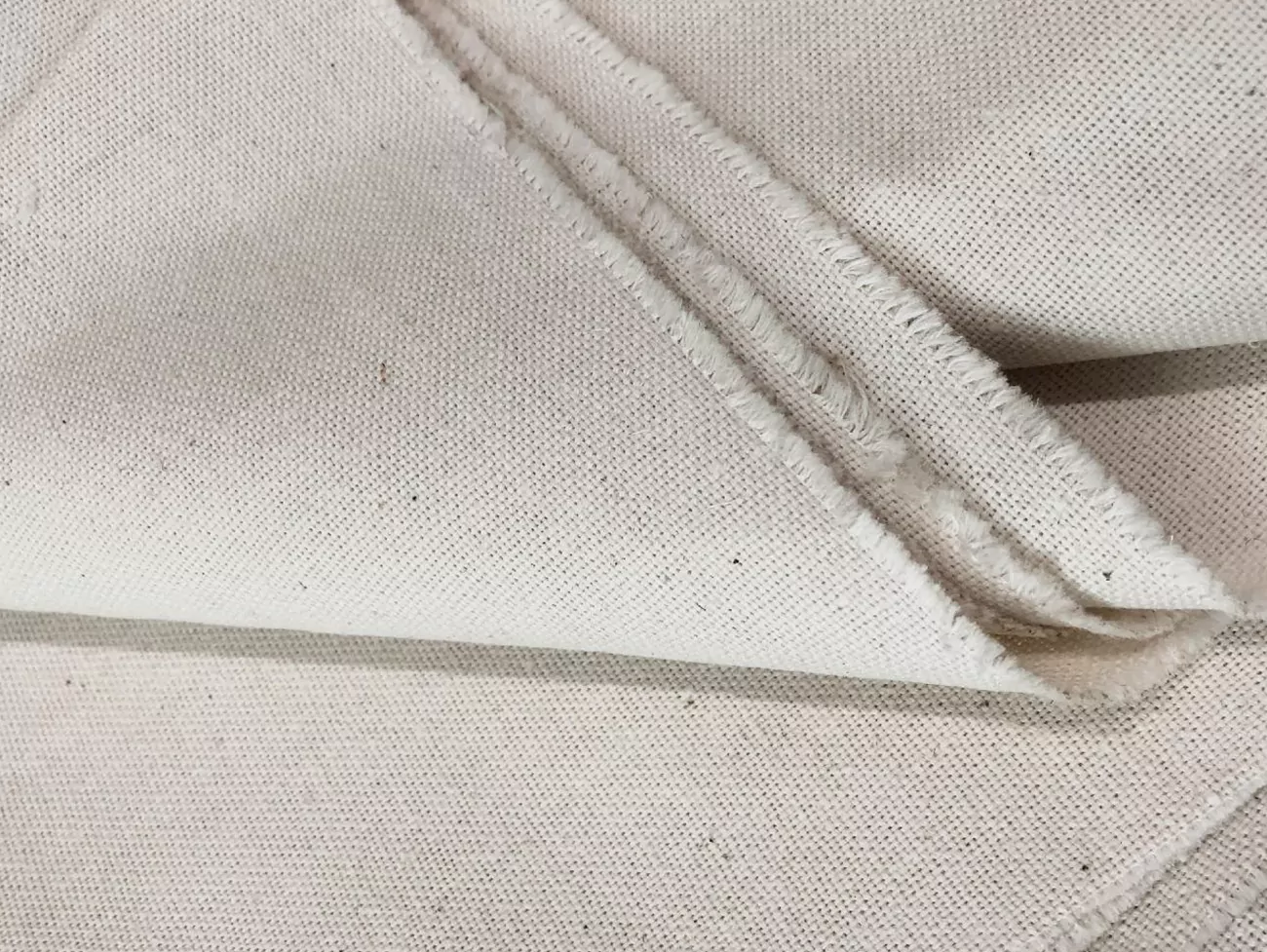

After the pineapple is harvested, the suitable plant leaves left behind are collected into bundles and the long fibers are extracted using a semi-automatic machine. The fibers are washed and then dried naturally in the sun, or in ovens during the rainy season. The dried fibers undergo a purification process to remove any impurities, resulting in a fluffy material.

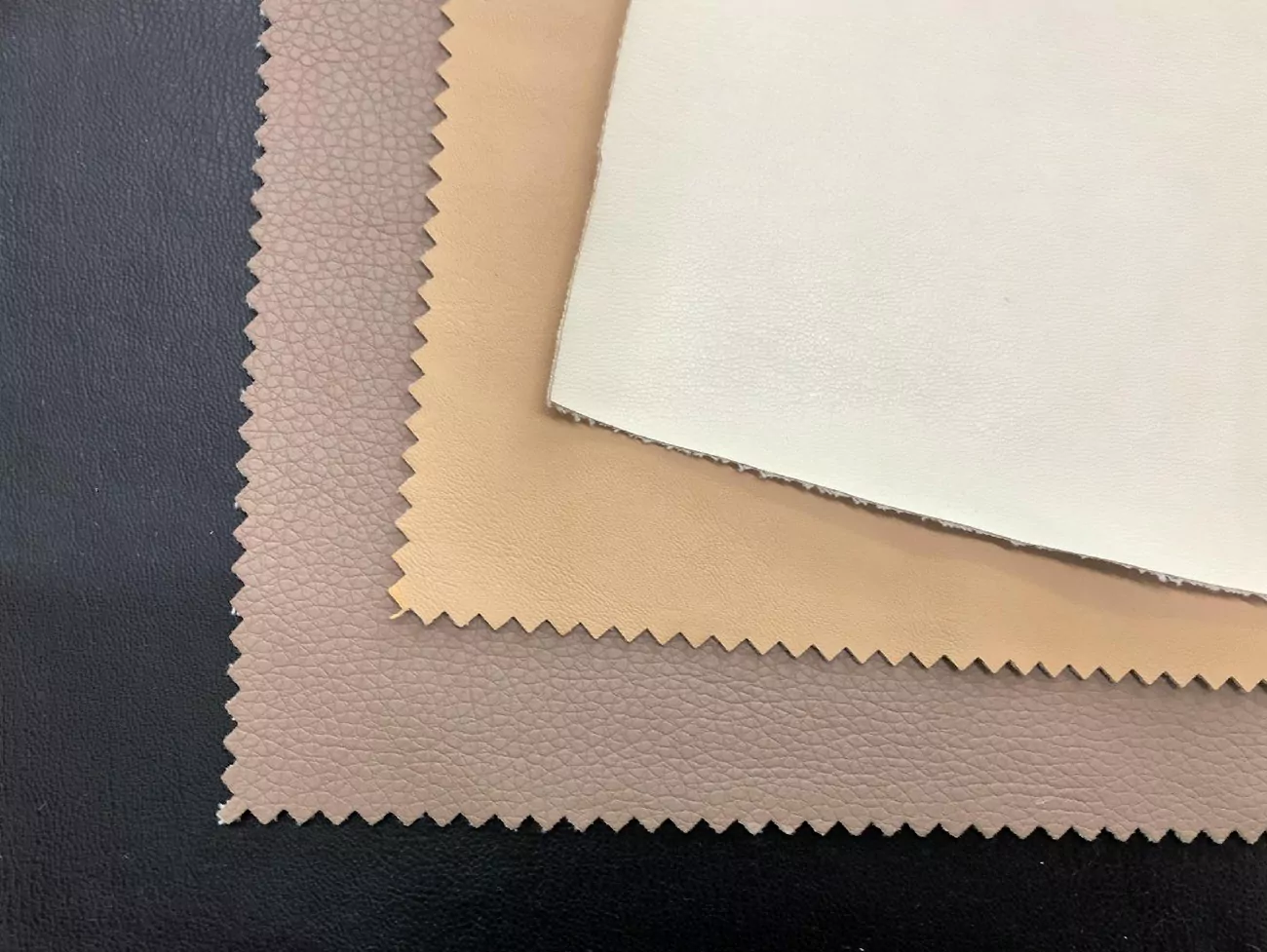

All Vegan Product Certification

2025 © Copyright Guangzhou C&T Industry Company Limited