About Us

Flexible Customization and Fast Delivery for Brands Since 2006

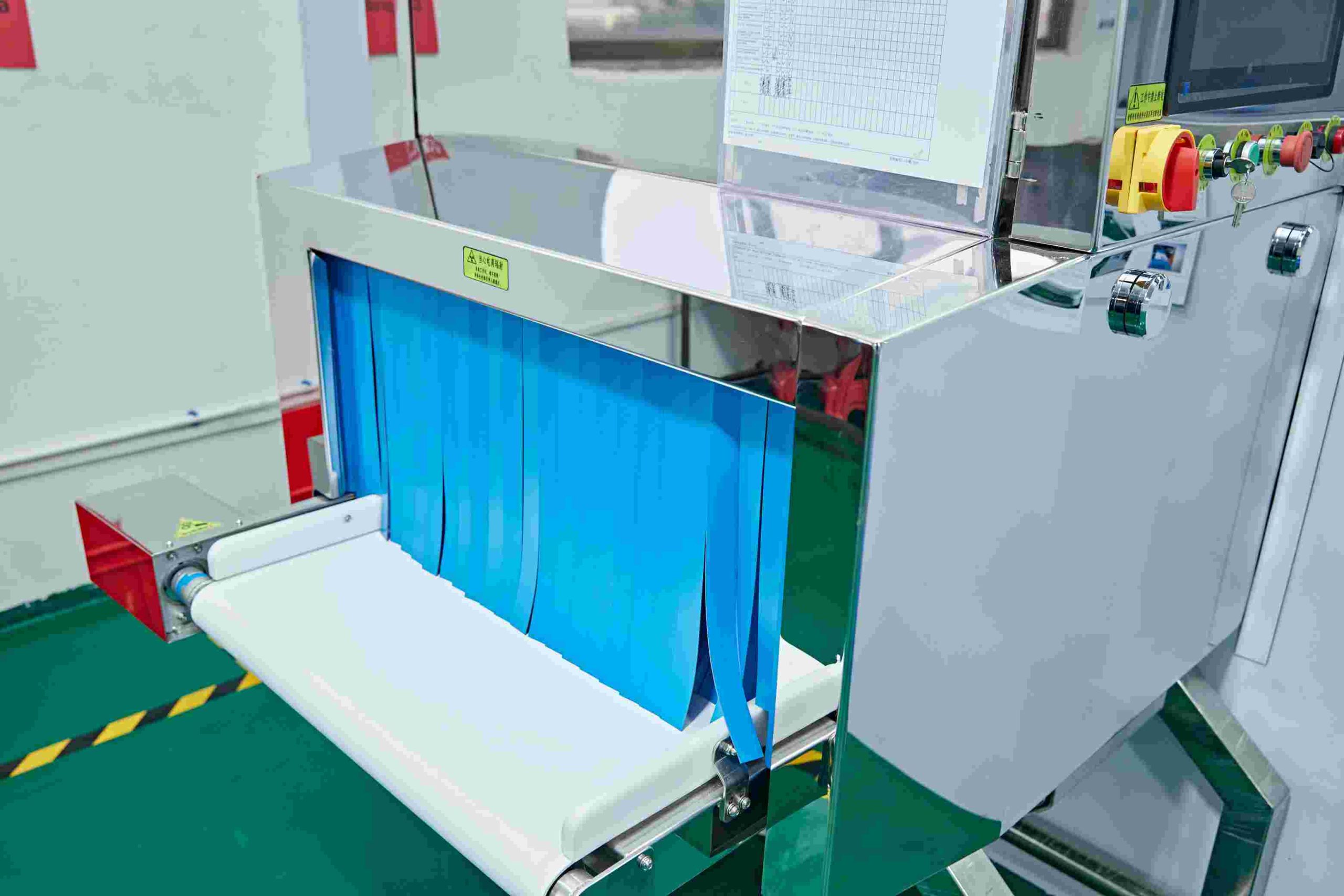

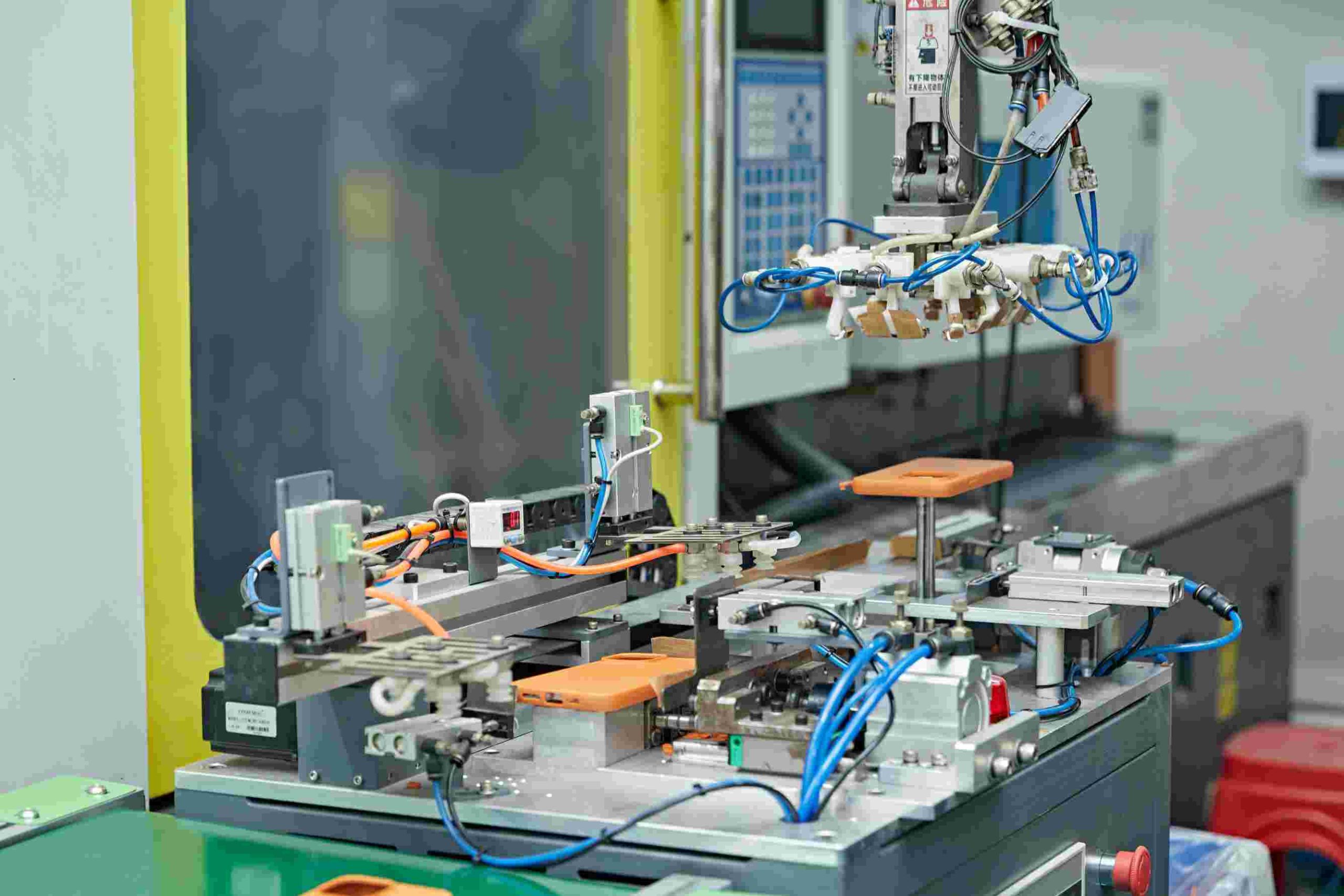

Automated injection workshop / Leather sewing workshop / Packaging workshop

8000+ ㎡

Factory Area

3-7Days

Sampling time

80%

Automation equipment

First

GRS certification

500+

Employees at 2022

18+

R&D Team

20+

Certificates

1800W+

Capacity / Year

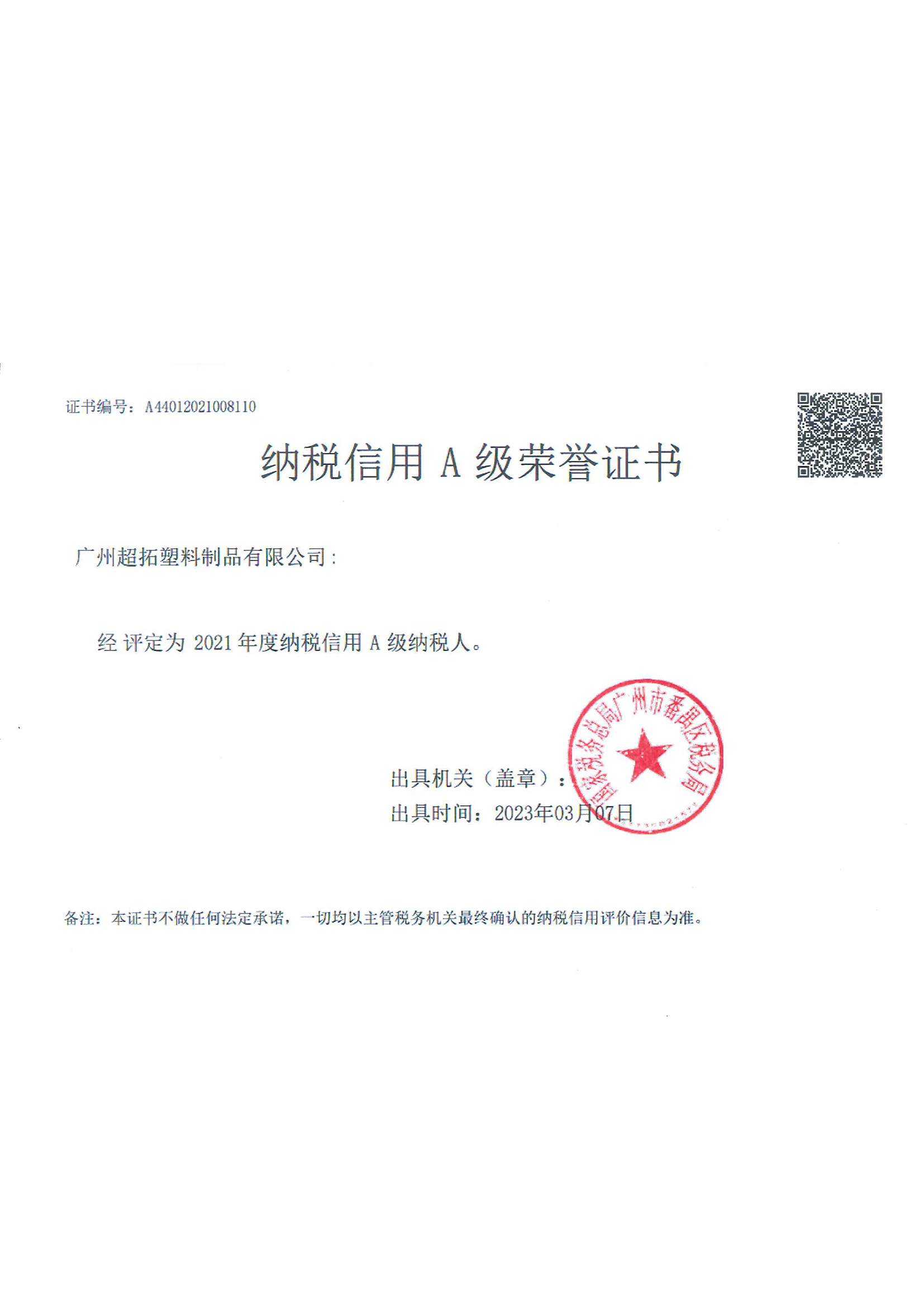

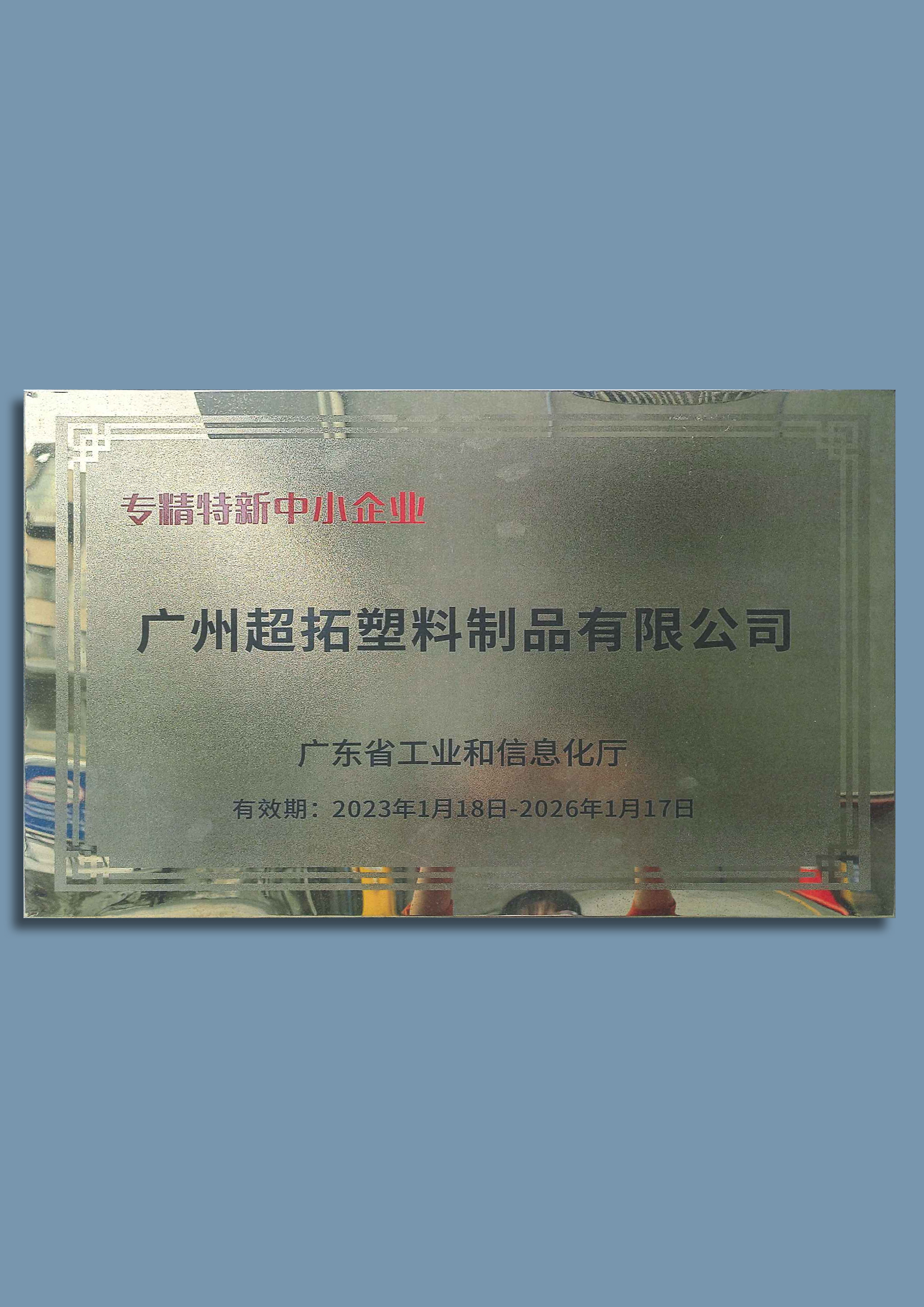

Company Certification

30+ factory inspections/year, our achievements are yours.

Beginning

Enter the mobile smart accessories industry

Rising with Apple

Expansion

Factory Establishment;

OEM service;

Layout in developed countries

Layout

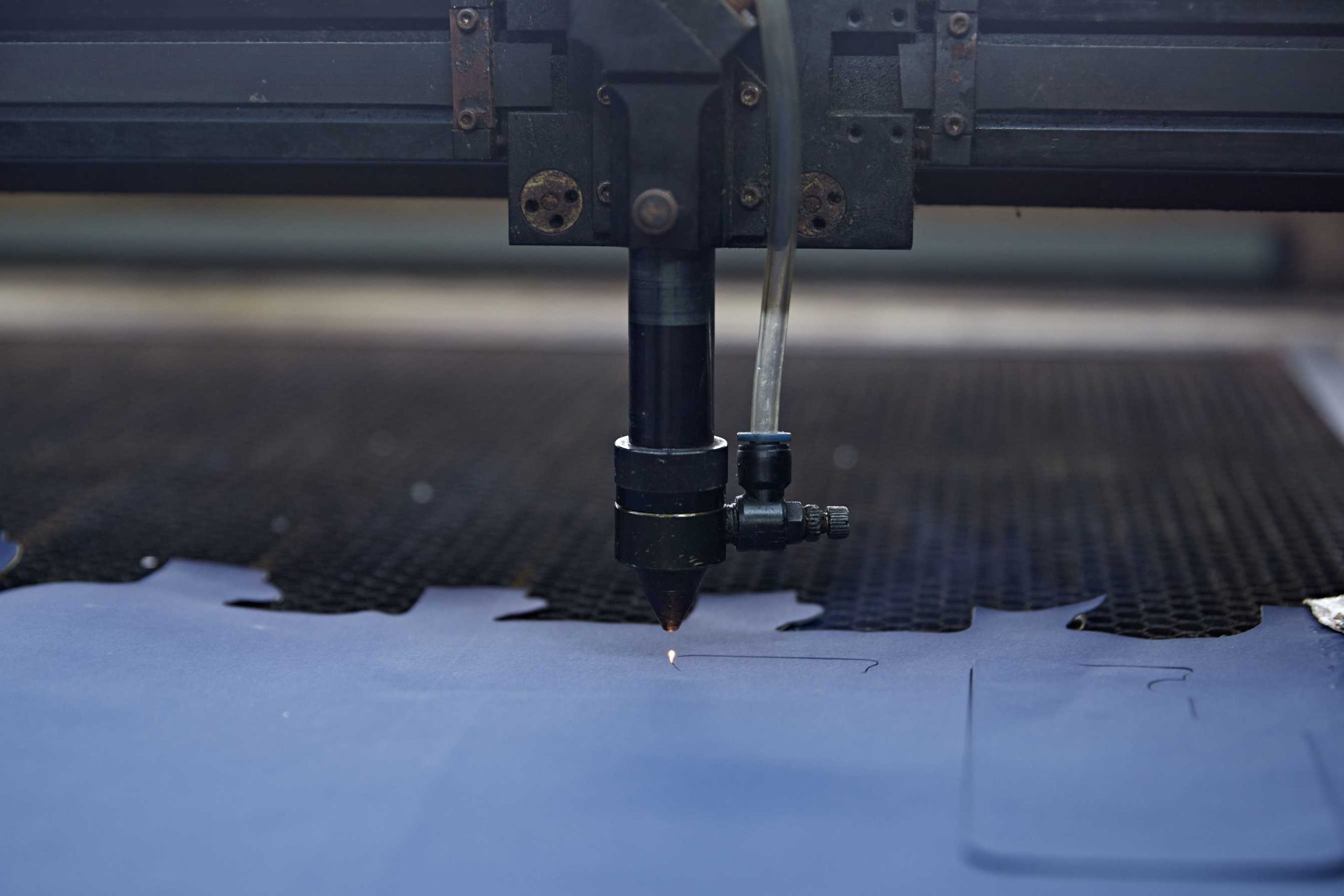

Automated equipment production;

Passed international quality and management certification;

Investment in R&D and design

Journey

Provide industry data analysis;

Lay out sustainable development;

Transform ODM customized services

Innovation

80% environmentally friendly material products;

AIGC: Intelligent Generation Content;

80% automated production

- 80% automated production

- 100W/month production

- Mold makers with over 15 years experience

- Imported precision equipment

- Five specialised production lines

- Mold makers with over 20 years experience

- 30W/month production

- There are 5 packaging lines, for example, packaging capacity of 120W-150W/month

- Automatic needle detectors equipment

- Automatic barcode scannerfor each packaging line

- Carton Sealer

- NDA training for customer production

- Enjoy independent and priority production line

- Customer rights protection management

- Third-party professional destruction

Ethics and Production

Ethics and compliance

A safe and respectful workplace for everyone

Greener factories, greener communities.

A safe and respectful workplace for everyone

Greener factories, greener communities.

R&D Team

C&T's investment in product R&D and innovation accounts for 5-10% of the company's annual marketing expenses.

Engineering Team

21+engineers(PE/IE/ME/BOM...)

Improve process flow to enhance quality, efficiency, and fast delivery in a short time.

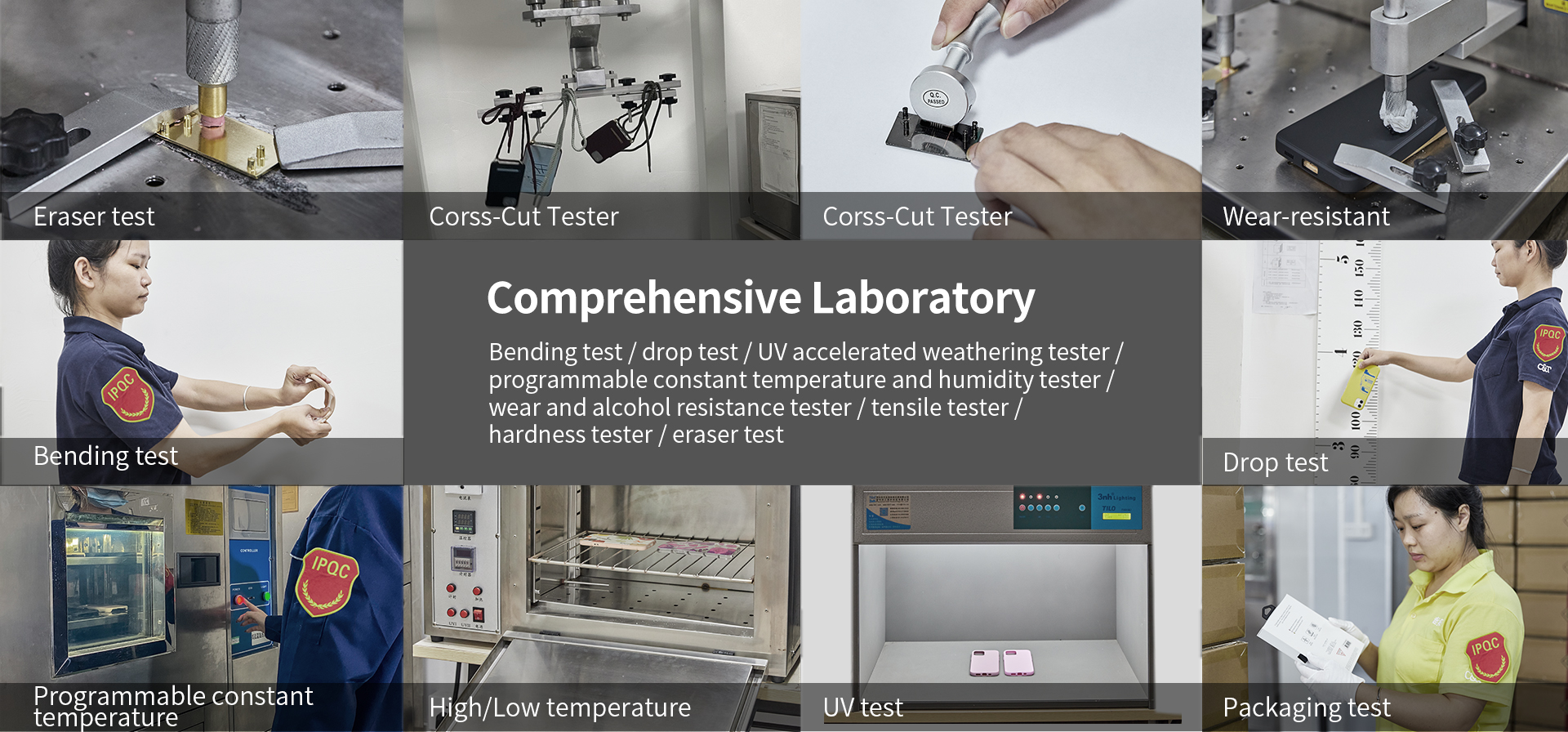

Quality System

15+people team

1st comprehensive laboratory in the industry product test report(All materials、safety test、screen test、Glue test、Hardware accessories test)

Complex Laboratory

10+ prodessional testing equipments, 20+ testing, for product quality escort

Customer Cooperation Cases

The European and American markets have become C&T’s core target markets, with a market share of up to 80%.

C&T provides specialized flexible customization solutions for more than 100 international famous brands in the world, and responds quickly to the ever-changing needs of the market.

0

+

Cumulatively served 720+ clients

0

+

Serving over 12+ industries

0

+

Internationally renowned brand clients

Cooperation Brand

Accreditations

- Specialized in special new enterprises

- New high-tech enterprise

- Integrate IT application with industrialization

- Innovative small and medium-sized

- Tax grade A

- Won the 2023-2024 Innovation Design Gold Award at CES 2024